Paddle Level Switch

Paddle Level Sensor

Powder Level Sensor

Grain Level Switch

Introduction

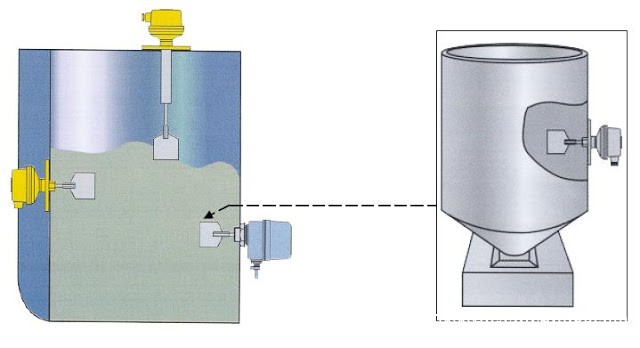

The paddle of the sensor rotates 1 time per minute. As the content in the tank fills up and influences the rotation of the paddle to stop, the relay in the sensor activates.

Paddle Level Switch

Paddle Level Sensor

Powder Level Sensor

Grain Level Switch

Introduction

The paddle of the sensor rotates 1 time per minute. As the content in the tank fills up and influences the rotation of the paddle to stop, the relay in the sensor activates.

Paddle Level Switch

Paddle Level Sensor

Powder Level Sensor

Grain Level Switch

Introduction

The paddle of the sensor rotates 1 time per minute. As the content in the tank fills up and influences the rotation of the paddle to stop, the relay in the sensor activates.

Paddle Level Switch

Paddle Level Sensor

Powder Level Sensor

Grain Level Switch

Introduction

The paddle of the sensor rotates 1 time per minute. As the content in the tank fills up and influences the rotation of the paddle to stop, the relay in the sensor activates.

Feature

■ Easy to install, and used in low or high temperature.

■ Used for fodder, grain, powder, etc.

■ Robust structure and able to adjust the length of axis.

Applications

-

Plastic surgery equipment

-

Plastic mixer

-

Paint solid mixer

-

Tube conveyor equipment

-

Pulverizer

-

Various types of molding equipments

-

Rice cleaner

- Grain mixer

- Dryer

- Mill

-

A/S Check Point

If you find any abnormal symptom during operation, please try to check below points.

■ Is the sequence circuit set correctly?

■ Isn't the lead line cut or short-circuit?

■ Is the float installed correctly regarding the direction or point?

■ Is there output through the lead line when you move the float up and down?